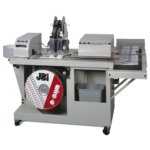

- Maximizes productivity at up to 8,400 cycles/hour, at up to 20 sheets of 60# offset.

- Will handle a sheet sizes from a 4 1/4″ (punched edge) x 3 7/8″ (non-punched edge) to a max size of 15″ x 15″.

- Allows you to punch tabbed stock pre-collated into the book. Tabs must have a minimum of 1/4″ shoulders. For larger width applications the Lhermite EX610 Auto Punch will handle widths up to 24″

- Reduces the minimum unbound edge to 5 1/4″.

- Punches virtually any type of stock and material for practically any application.

- Continuous paper loading speeds productivity without stopping the machine.

- Automatic sheet alignment with micro adjustment. One-direction, one-level continuous sheet control.

- Heavy Duty Steel Dies that feature guide posts for perfect alignment, quick pin access, and flanged holes to help clear out waste and add longer life.

- Turnover Drum that keeps pre-collated document pages in perfect order.

- Easy to use, fast and simple to setup and operate.

- Continuous loading top feed trays speed up productivity without stopping the machine.

- Separator Beak separates lifts of paper, even thicker stocks, without damaging the edge.

- Heavy duty tempered steel die changes are quick and easy.

- A wide range of die patterns including: 3:1 & 2:1 Wire-O®; 4:1 UniCoil® plastic coil; plastic comb; Velobind®; 2, 3, & 4 ring binder; spiral; etc.

Optional Features:

- Optional Tabbing Device for punching tabbed sheets. Tabs must have 1/4″ shoulder.

- Choose between two delivery options. A variable speed conveyor for continuous delivery, shingles sheets as they exit the turnover drum and conveys them out to the operator. Or a high pile delivery neatly stacks and continuously jogs the paper and automatically recedes to allow your operator to concentrate on loading the paper feeder. Automatically stops when full.

- An Air Blow option provides a blast of air to separate the picked lift from the stack. Helpful for stocks or environments where static is a common problem. Includes air lines only – air compressor not included.